Cooling Induction Systems

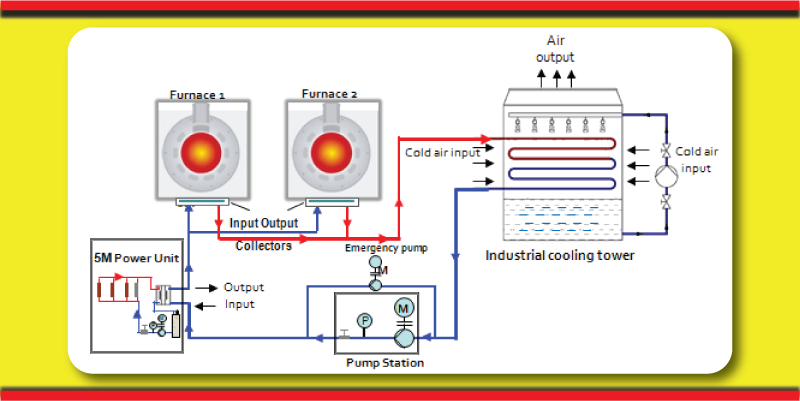

Many different types of cooling systems exist for induction applications. Some systems include recirculating water systems, and air cooled systems. Each type of systems has various parts and can be broken down further into closed or open. We will focus on the advantages, and common understandings of each system.

Water systems supply a controlled temperature of cooling for the power supply, induction coil, the leads and bus, as well as the heat station. These units consist of heat exchangers, tanks, pumps, filter cartridges, and temperature controllers. The water used in the cooling of the system must not be too cold to avoid and prevent condensation in the power supply, heat station and coil. If the water is to cold, the electrical arcs can be damaged as well. High conductivity water should also be avoided. This causes the cooling system and power supply to erode due to electrolysis. Electrolysis is the separation of elements, copper specifically, which breaks down parts. The parts then create debris that can create an opposite polarity which reduces the flow found in a circuit. A lower water flow raised the operating temperatures of a unit, which leads to a shortened shelf life of the unit.

Air cooled systems cool the induction heater by the means of wind. This can be done by fans cooling the heater via copper or stainless steel tubing, or by cooling recirculating water. Both processed are advantageous by having little or low maintenance and using low horse power. These separately or in combination equals lower operational costs. It is important to have the cooling apparatuses in proper placement. Ideally they are places on the north side of building avoiding direct sunlight. Ideally both the copper/stainless steel tubing and recirculating water will want to have fresh and cool air as possible.

Air cooled systems cool the induction heater by the means of wind. This can be done by fans cooling the heater via copper or stainless steel tubing, or by cooling recirculating water. Both processed are advantageous by having little or low maintenance and using low horse power. These separately or in combination equals lower operational costs. It is important to have the cooling apparatuses in proper placement. Ideally they are places on the north side of building avoiding direct sunlight. Ideally both the copper/stainless steel tubing and recirculating water will want to have fresh and cool air as possible.