Induction Heating in the Industry

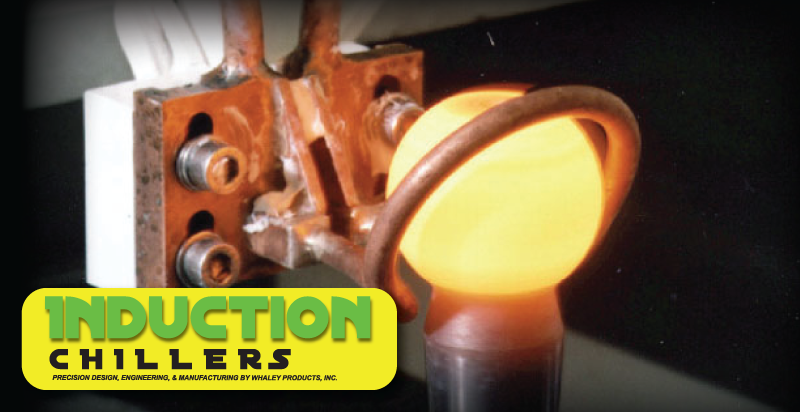

Induction heating has been adapted to fit many different industries inside the manufacturing market. Different markets can include the automotive industry, the aviation industry, and the shipbuilding industry. Different heat treatments are used in the different industries. Some can include brazing, hardening, or tempering. Brazing is when metals are joined together by melting and flowing a filler metal into a joint. The filler metal has a lower melting point that the adjoin metal. Hardening a metal increases the toughness of the metal. Tempering metal is the process is used to increase the toughness of iron based alloys. These are just a few of ways induction is used in heat treating.

Different industries require different ways of using induction heating. In the automotive industry induction heating is used bond parts, like rear view mirrors. It is also used to preheat materials This allows the reduction of cracking and hardening structure. This is due to the material generating heat within is self. The cracking and hardening can occur when the outside temperature of the material is lower than the internal temperature of the material.

Aviation and shipbuilding are common industries that uses induction heating. Induction brazing is important because heat must be accurate, controllable and consistent to the production of parts. Brazing is used for the creation of fan blades and fan blade casings. It is also used for the parts for fuel systems and components of a hydraulic system. Shipbuilders use induction heating to reduce the risk of fire. When straightening metal for decks or bulk heads, heat is applied in specific patterns to deformed areas of steel. Induction is better used because it does not require direct heat.